|

| March 22, 2022 | Volume 18 Issue 12 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

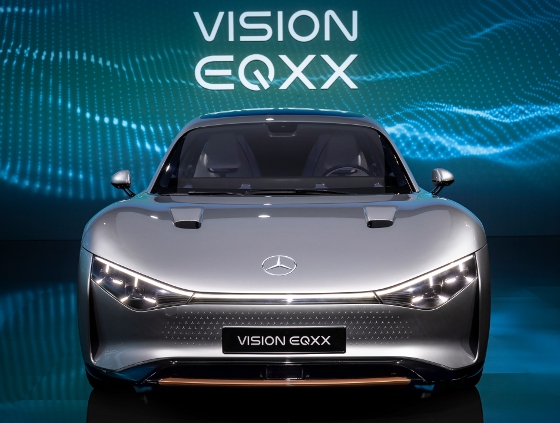

Mercedes aims for 620 miles (1,000 km) on a charge with VISION EQXX all-electric sedan

What does the future of all-electric driving look like over at Mercedes-Benz? It's smaller, smarter, streamlined, and a long-distance runner -- and it's called the VISION EQXX. This real-world concept uses the latest technologies in batteries, materials, electronics, and Formula 1 to provide up to 620 miles (1,000 km) on a single charge and a luxe interior experience that aims to please. It uses a little solar power too.

In February 2021, the car-shopping experts at Edmunds published the results of their real-world driving tests for electric vehicles (vs. EPA estimates). The rear-wheel-drive Mercedes EQS 450+ sedan (an all-electric version of the S-class) with a 245-kW electric motor came out on top, with a real-world range of 422 miles on a single charge (a full 77 miles ahead of No. 2 Tesla Model 3), so it's looking quite possible for Mercedes to reach its goal of over 600 miles and beyond.

The VISION EQXX concept is a rear-wheel-drive car too with a single electric motor, but Mercedes has not given full specs on the powertrain -- only that the motor output would be "around 150 kW." That's a lot less than many of the high-end EVs we've see, but this car has a strong focus on efficiency.

Lightweighting tech and efficiency highlights

What we do know is that the company has put considerable effort into the battery development, with a goal benchmark efficiency of "95% from battery to wheels," meaning up to 95% of the energy from the battery ends up at the wheels. To that end, Mercedes-Benz R&D worked with the Formula 1 experts at Mercedes-AMG High Performance Powertrains (HPP) in Brixworth (UK) to redesign the drivetrain and slash the system losses. The electric drive unit in the VISION EQXX is a dedicated unit consisting of the electric motor, transmission, and power electronics featuring a new generation of silicon carbides. The power electronics unit is based on the upcoming Mercedes-AMG Project ONE hypercar.

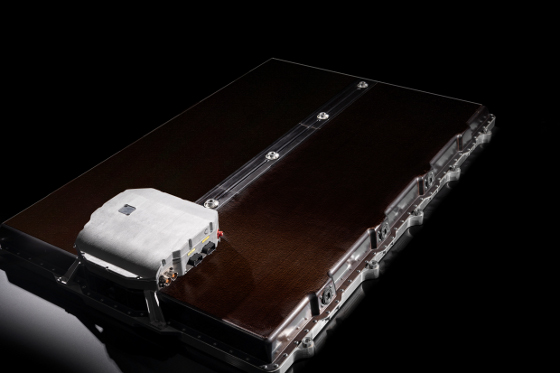

Rather than simply increasing the size of the battery, Mercedes-Benz and the HPP team developed a completely new battery pack for the VISION EQXX, achieving a remarkable energy density of close to 400 Wh/l. This benchmark figure is what made it possible to fit a battery pack with just under 100 kWh of usable energy into the compact dimensions of the VISION EQXX. "In effect, we fitted the energy of the EQS into the vehicle dimensions of a compact car," says Adam Allsopp, advanced technology director at HPP. "The battery has almost the same amount of energy but is half the size and 30% lighter. The battery management system and power electronics have been designed with an absolute focus on reducing losses. In achieving this efficiency milestone, we learned a lot that will flow into future development programs."

The substantial increase in energy density comes in part from significant progress in the chemistry of the anodes. Their higher silicon content and advanced composition mean they can hold considerably more energy than commonly used anodes. Another feature that contributed to the impressive energy density is the high level of integration in the battery pack. This platform, developed jointly by Mercedes-Benz R&D and HPP, created more room for cells and helped reduce the overall weight. The separate compartment for the electrical and electronic (EE) components, called the OneBox, likewise made more room for cells, with added benefits for installation and removal. The OneBox design also incorporates novel safety devices with energy-efficient operations that consume significantly less energy than the equivalent component in a production EV.

The battery development team also decided to experiment with an unusually high voltage. Increasing the voltage to more than 900 V proved an extremely useful research tool for the development of the power electronics. The team was able to gather a great deal of valuable data and is currently assessing the potential benefits and implications for future series production.

Several more aspects of the battery design add to its exceptional efficiency. For instance, its lightweight lid was engineered jointly by Mercedes-AMG HPP and their chassis partners at Mercedes-Grand Prix. The lid is made from a unique, sustainable composite material derived from sugar-cane waste and reinforced with carbon fiber, as used in Formula 1. The battery also features active cell balancing, which means drawing the energy evenly from the cells while the car is driving -- in effect, giving it greater stamina. Overall, the battery weighs around 1,091 lb, including the OneBox.

VISION EQXX also sports an innovative thermal management system. The Mercedes-Benz "cooling-on-demand" concept has been further developed for optimal cooling based on the prevailing circumstances. The exceptional efficiency of the electric drive unit means it generates only minimal waste heat. This helped keep the thermal management system extremely small and lightweight. The carefully engineered interaction of aero-shutters, coolant valves, and water pumps ensures the electric drive unit, comprising the power electronics, electric motor, and transmission, maintains the most efficient temperature balance at minimum energy cost. Technically, this system is a combination of an innovative air-flow management system and a cooling plate.

The cooling plate is installed in the vehicle floor, enabling it to take advantage of the air flowing along the underside of the VISION EQXX. According to Mercedes-Benz, this is the most aerodynamically efficient way of keeping the electric drive unit cool under normal conditions, allowing the vehicle to gain about 20 km (12 miles) of range in the most aerodynamic mode.

VISION EQXX also makes use of an innovative heat pump that sucks up heat generated by the drive system and from the ambient air outside to keep the cabin cozy. Its impressive efficiency is a major boost for battery range in colder parts of the world. This multi-source heat pump recovers waste heat from the drivetrain and has an external heat exchanger that draws heat from the ambient air. Not available in previous Mercedes-Benz heat pumps, this feature increases the operating temperature range. This is especially handy for heating up the cabin quickly and is highly effective at lower temperatures.

Solar panels help with efficiency too. The electric system that powers many of the ancillaries in the VISION EQXX draws additional energy from 117 solar cells on the roof. It was developed in collaboration with the Fraunhofer Institute for Solar Energy Systems ISE, Europe's largest solar energy research institute. The net result of reducing the energy drain on the high-voltage system is an increase in range. On a single day and under ideal conditions, Mercedes says this can add up to 15 miles (25 km) of range on long-distance trips. The solar energy is stored in a lightweight lithium-iron-phosphate battery, which supplies a climate blower, the lights, the infotainment system, and other ancillaries. Mercedes-Benz and its partners are working toward using solar power to charge the high-voltage system too.

Lightweighting has been key. The MS1500 ultra-high strength martensitic steel used in the VISION EQXX marks a first for a Mercedes-Benz body-in-white application. The exceptional strength of this material offers excellent occupant protection in the event of a crash, while keeping weight to a minimum. The doors of the VISION EQXX are made from a hybrid of CFRP and GFRP (carbon- and glass-fiber reinforced plastics) components with aluminum reinforcements. A new polyamide foam reinforces the lower edge of the door and optimizes energy absorption in a side-on collision. On the chassis, aluminum brake discs reduce the mass significantly compared with cast steel discs. New advanced glass-fiber-reinforced plastic springs developed in partnership with Rheinmetall Automotive remove further weight compared with conventional coil springs.

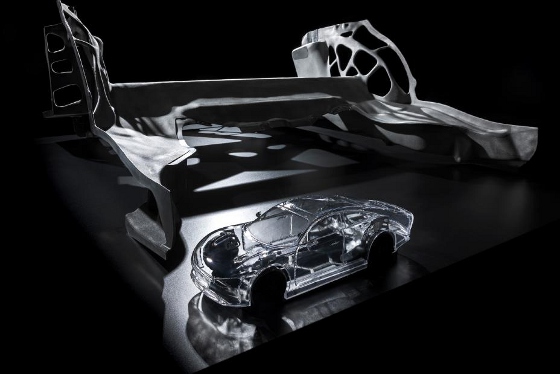

BIONEQXX is the name of the major structural component at the rear end of the VISION EQXX -- the rear floor. It is the largest aluminum structural casting at Mercedes-Benz. It has a web-like appearance and was developed in-house by Mercedes-Benz using entirely digital techniques and a generative design that focuses on bio-inspired shapes and efficiency.

Taking their cues from organic forms, the development engineers sought to use material only where loads are exerted. Mercedes says, "The beauty of the one-part BIONEQXX casting is the ability to pair this with functional integration within an extremely lightweight single component rather than an assembly of multiple parts joined together." The generative design approach was used for other components in the car too.

Mercedes also spent a good deal of time and effort on maximizing the aerodynamics of the VISION EQXX, achieving an impressive benchmark drag coefficient of cd 0.17. The surfaces of the VISION EQXX run smoothly from the front, developing powerful rounded shoulders above the rear wheel arches. This natural flow concludes with a cleanly defined, aerodynamically effective tear-off edge accentuated by a gloss-black end trim, punctuated by the rear light clusters.

Painted in Mercedes-Benz alubeam silver, the body of the VISION EQXX cradles the smooth dome of the greenhouse as it flows like a water droplet toward the rear. The retractable rear diffuser is an example of the collaboration between design, aerodynamics, and engineering -- deploying only at higher speeds when the air becomes a considerably tougher opponent. When retracted, it fits seamlessly into the bodywork, preserving the balance, proportions, and lightweight aesthetic of the rear end.

Not so obvious at first glance is that VISION EQXX has a very small frontal area, which is less than that of today's CLA or even the vehicles from smart. The rear track is also 2 in. less than at the front. Another hidden feature is the air curtain at the front bumper. This layout pairs with the specially designed wheel covers to remove almost every last whisper of aerodynamic separation from the 20-in. front wheels.

Inside, the four-seater VISION EQXX is luxe all the way, with a simple design that taps into a sporty, almost yachty feel that we've seen from this brand in the past. It's all lightweight, sustainable materials and organic-inspired design detailing. You can't help but notice the completely seamless display that spans 47.5 in. from one A-pillar to the other. The Mercedes-Benz team worked with navigation experts NAVIS Automotive Systems (NAVIS-AMS) to develop the first real-time 3D navigation system on a screen of this size. It performs seamless zoom and scroll functions from satellite view down to a height of 33 ft in the 3D city representation.

A single charge of the VISION EQXX would take you from Berlin to Paris, from New York City to Cincinnati, or from Beijing to Nanjing. It will be interesting to see how much of this tech makes its way into future Mercedes-Benz EVs. Given the brand's history of concept development, it should be a good deal of it.

Source: Mercedes-Benz

Published March 2022

Rate this article

View our terms of use and privacy policy